Kitchen Knives - Sharpening

| Home |

There are many ways to sharpen a kitchen knife. The best way to sharpen a kitchen knife is often. It is easier to keep a knife sharp than to have to do a major repair.

KITCHEN KNIVES AND SHARPENING STEELS

Traditional Sharpening Steels

A traditional Sharpening Steel is a hardened steel rod tapered to a point usually with a protective guard and handle with a carry ring or place to attach a ring. The handles of a Steel are generally made of either a synthetic or wood. The Rod is usually smooth, or lined with grooves of fine or coarse design running parallel to the rod length. The tip of the steel is generally magnetic to catch any stray metal that may be dislodged from the edge of the knife being sharpened.

A traditional Sharpening Steel actually doesn’t do much sharpening as defined by removing metal from the blade edge. What a Steel does accomplish is the straightening of the ultra fine cutting edge as it is distorted from the cutting process. This distortion is caused by the edge impacting a hard surface such as bones, cutting board surface, etc. For a cutting edge to slice efficiently it must be straight and without roll or deflection. If it is rolled to one side or if it is deflected along its length, it will drag and bind as it makes its cut, this drag or binding will produce drag and friction and the knife will not cut smoothly. By using a steel to straighten an edge when needed, as opposed to steel removal due to actual sharpening, increases the life span of the knife’s cutting edge. This function is very important to a Butcher or Professional Cook who may use his or her knife as much in a day as the normal household may in several months. A professional that is continually removing steel from his expensive cutlery every few minutes will reduce the life expectancy of his knives greatly. It is much better to straighten the edge and only sharpen when needed.

The Steel can be used in a variety of different ways. A Professional may hold the Steel in one hand and quickly stroke the knife edge along the surface of the steel on the top side and then the bottom side. They perform these actions so quickly that it appears effortless and easy. I assure you that it is not easy. The Professional through years of practice maintains a precise angle to Sharpening Steel that is not apparent. To the untrained cook a couple of imprecise strokes will do your knife edge more harm than good. It is much better for the beginner to try a slower more studied approach. Remember that the Sharpening Steel rod is tempered much harder than the steel on your knife edge, it can and will destroy that edge if used improperly.

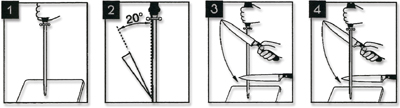

JA Henckels recommend that the Steel be placed perpendicular to a kitchen counter top with the rod’s point resting firmly on the surface. In this position you can see the angle made by the edge to the rod. In a slow deliberate stroke move the knife edge from heel to tip from top to bottom of the rod while moving down and drawing the knife at the same time and then repeat on the other side of the Steel.

JA Henckels Instructions:

There are also two modern versions of the traditional Sharpening Steel. One utilizes a fine grit ceramic material either solid ceramic or ceramic applied to a metal rod, flat or oval. The other is a metal rod either round, oval, or flat with a diamond coating. Both of these styles are often referred to as Sharpening steels but they are not so in the traditional sense. Both of these modern versions actually remove steel from the blade edge, the ceramic models less so than the diamond models. They are used in much the same manner as a traditional Steel, with a few slight differences.

Ceramic Sharpening Steels

These products have been around for over twenty years. They are used and loved by many of my customers and I use them myself in certain situations. They have their place but they also have a couple of drawbacks for the casual user, especially if you have teenagers or heavy handed spouses in the house. Their main problems are they are relatively easy to damage and the skill level for proper use increases. One good drop onto a tiled kitchen floor or granite counter top and the chances of the ceramic material breaking in half is pretty well guaranteed. Even the newer ceramics bonded to a metal base will chip and wear prematurely. Since these ceramic steels actually remove a fine line of metal from the edge it is my opinion that a more precise technique is required in their use than the traditional metal Steels which merely straighten an existing edge. The wear and breakage problems combined with the problems of accurate technique would seem to make them problematic for many casual users. Now if your technique is accurate and you never drop them and your teenagers never use your knives or sharpening device then they may work fine. You know your situation better than I.

Diamond Steels

The diamond steels are usually a metal rod, oval, or flat with about a 600 grit diamond cutting face bonded to a metal surface. There are two styles of diamond surfaces monocrystalline (mono) and polycrystalline (poly). The mono style (usually the more expensive of the two) is single headed diamond and the poly style (usually the cheaper of the two) is a multiple headed diamond. I prefer the monocrystalline style of diamond rather than the polycrystalline surface. The mono style is more uniform and doesn't require a break-in period as does the poly style. The poly style diamond is rough and inconsistent as received and requires a break-in period to smooth the diamond surface enough for normal use.

I myself use a diamond steel in the kitchen for most all of my knives (except for my Shun, they hardly ever need sharpening). Diamond steels also put a tooth back into the edge which some gourmets prefer to a smoother polished edge. As with the ceramic steels, since you are actually removing steel, the sharpening angles and techniques must be precise. The diamond steels are also good as an intermediate sharpener when a traditional steel isn’t bringing the edge up to a sufficient sharpness but the edge is not so mangled that it need to be completely reworked on a benchstone.

Care of Steels

Most traditional steels require little maintenance but they do require cleaning. Since you may go directly from fresh meat to a steel and back it is as important to keep your steel clean as it is your cutting board. They need to be cleaned after use with a little soap and hot water. Scrub brush them clean. Be sure to dry them thoroughly. Do not set the steel out to dry on the drain board or put them in the dishwasher, depending on the material in its manufacture you may rust the steel or damage the sharpening grooves, handles or both. Ceramic steels and diamond steels will tend to pick up metal particles so they need to be scrubbed with an abrasive cleaner such as Comet or Ajax. Use a scrub brush or old stiff toothbrush on the diamond steel or a little abrasive cleaner on a wet dish towel in the case of ceramics. Ceramics tend to get black lines on them; these lines are metal particles from the blade. You can minimize these marks with an abrasive cleaner although you probably will not be able to get them as pristine as when new. Occasionally inspect your traditional steel to see that there are no horizontal nicks across the grooves, these nicks will instantly dull your knife. Old rusty steels that have lost the "tooth" to their sharpening grooves need to be discarded and replaced with new. Steels will wear out and old steels usually are worn out.

Remember that sharpening steels are just for touch-ups and basic maintenance; eventually you will need to have the edges of your knives re-cut on a good quality bench stone or re-cut by a professional sharpening service. Edges that see constant use will round out and lose their bevels, then no amount of steel touch up will restore the cutting edges. A good quality knife with a steel blade, that is not abused, and is touched up after use should only need re-cutting every 6 months to a year for the normal household, Professional user may need re-cutting more often.

I have run a professional sharpening service for over 20 years and sell all of these different steels, my observations and opinions are made from actual use and from discussions with my customers who use these products, this is not just a regurgitation of all ready published literature. My philosophy is that there are many ways to travel to and arrive at the same destination; there is not a right way or wrong way it only matters that the results are those you prefer.

NEXT - SHARPENING STONES